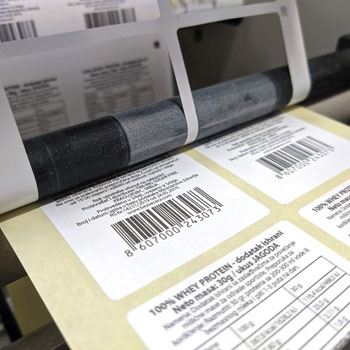

Variable data labels

- printing from a database

- on several types of media (paper, synthetics, void)

- black and white and color

- sheet or roll labels

- EAN13, Code 128, QR code, numeric and alphanumeric codes

- flexibility in the form and size of labels

- possibility of varnishing or lamination for additional protection

Materials and forms

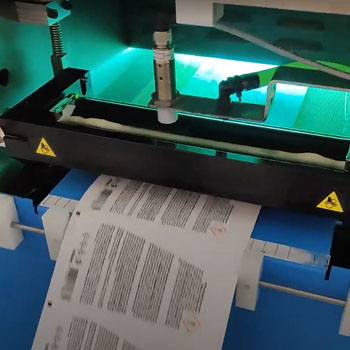

We manufacture stickers with changeable and unchangeable data, customized to your requests and needs on self-adhesive paper or foil, black and white or in color.

Labels can be sheet or roll labels, depending on the method of application (manual or machine).

Depending on where the labels will be used, there is the possibility of varnishing or lamination, which makes the labels waterproof and additionally protected from mechanical and other damage. We are flexible in terms of die cutting the shape and size of labels.

Short production time

In the case of simpler orders, we are able to manufacture labels within a few days. In some cases it is possible to manufacture them in one day once the order has been received.

Printing from a database

If there is more variable data on the label, it is usually printed from a database. The variability of data, text, barcodes and QR codes, numbers, pictograms and images is theoretically unlimited.

Where are these labels used?

- Product labels

- Envelope addressing labels

- According to a certain algorithm

- Labels with activation code

Barcode and QR code labels

- The content of the labels can be the same, if the same barcode or QR code is used for all products

- Variable labels, which are used to identify items, e.g. inventory items

- Stickers printed from a file: from Excel spreadsheets with multiple types of data

Numerical and alphanumeric codes

Sequence variability may be increasing (1, 2, 3, 4, 5, 6); descending (6, 5, 4, 3, 2, 1); duplicated (1, 1, 2, 2, 3, 3, 4, 4); according to a certain algorithm (1, 3, 5, 7); with prefix or suffix (D00001, D00002 or 00001D, 00002D) etc.

Where are these labels used?

- Products with a unique identification number

- Identification labels for services

- Stickers with serial numbers for document tracking

- Library stickers

Areas of usage

Product labels

We all know them and we have all met them already. Barcode labels on products serve for quick identification of goods at the checkout counter, or when transporting or ordering goods. Barcodes are usually printed on the packaging of goods. However, it often happens that barcodes have to be added later, or changed on the packaging itself.

Warehousing and logistics

Today, barcodes play a central role in warehousing of goods and later, in logistics.

In the field of warehousing, they serve for quick and easy identification of individual items. With just one scan, it is possible to determine, and if necessary, change - the type, quantity, and many other parameters of an item.

Inventory stickers

In industries where records on the use and lease of items are kept in detail, barcodes have proven to be useful and reliable. Digitization, scanning, loading and automation simply leave no room for error.

Types/standards

EAN 13

EAN 13 (European Article Numbering) is an international bar code standard used to mark products in retail. If you produce (or trade in) a type of product, you will need to mark it with this bar code if you want to place it in retail outlets.

This bar code standard contains 13 digits, where the first three digits indicate the country of origin of the goods, and the rest carry information about the manufacturer, and about the goods themselves.

The EAN 13 bar code is assigned by the international organization GS1.

Code 128

By using code 128 we are able to display the complete ASCII table. In order to encode alphanumeric data into the shortest possible form, it is automatically varied between 3 sets of characters, A, B and C. Due to the high density of information contained and the ability to display the complete ASCII table, Code 128 is used very often.

QR code labels

It may seem to us that all QR codes are the same, however, they all carry different information. QR codes are easy to read with smartphones and most often lead us to a website, where we can get more information about a particular product.

What are the main benefits of barcode printing?

Millions of companies around the world rely on barcodes to improve data management and accessibility, reduce costs and increase productivity. This innovative and easily implemented technology helps companies in all industry sectors to profit by using barcodes.

- Accuracy – Labels improve data accuracy over 99% in the case of inventory by automated data collection, thus eliminating the possibility of errors.

- Efficiency – Labels increase efficiency (faster work and less time spent by workers) by replacing the manual inventory with an electronic one.

- Consistency – Labels ensure consistent and predictable operations for improving quality of work by eliminating the bottleneck effect when entering data.

Printed barcode labels are key components in the process of quick and easy identification. Although they seem banal at first glance, their advantages are indisputable. Whether they serve to track shipments, inventory items, products, barcode labels are reliable tools for managing a tracking system.

The most popular barcode standards are:

- EAN13 - za proizvode u prodaji

- Code128 - for internal identification

- Code39 - code for displaying the entire ASCII nomenclature

- QR code - for marketing purposes

- EAN 128, GS1 128 UPC 128 - these codes are used by suppliers of large retail chains for marking pallets

- EAN13+5 - for newspapers, magazines

- DataMatrix - when a QR code is not an appropriate solution and there is not enough space to insert a code